They Built It

|

| Group for Unity Development |

The purpose of this paper is to describe the method used

and results of a small irrigation demonstration project. However the real story

should be about the people that made the project a success and will be

responsible to carry out the program. The project was in Liberia, a West

African country. The people I met during the weeks of travel had as varied

backgrounds as the difference to be found between the African Atlantic coastal

tropical forests and inland savannas compared to the Ozark Mountains and the

Mississippi floodplains of Southeast Missouri.

Two men Saah Musha and Sheriff guided me on this trip

and gave critical advice. The members of the farm association Group for Unity

Development or GUD had several farmers as Robert Yowoe from Foya and labors as

David from Porlumba Poma who made important contributions to the project

development. This was important not just for their contribution, but since this

was their enterprise the operators buy in was critical.

Saah Musha is an Extension Agent for Lofa and Nimba Counties. He is not a Liberian government employee, but is employed by the Non-government Organization WINROCK. Sheriff was our driver and also adapt at building and fixing equipment used in the project. Both lived though the Liberian civil war. Saah is educated in Agro-Forestry at a Liberian technical college and did have to opportunity to put his education to work a short while before the civil war disrupted his career. His one comment was the mental waste of not being able to use his mind. Saah knew the scientific name of every tree in the Liberian forest and spoke English, French and his home Dialect Kissi. After teaching in Guinea for ten years he returned home and eventually selected for the Extension position.

Robert was the primary point of contact for the GUD. He

led the oil palm nursery workforce and led the discussion concerning management

decisions. His focus at the time of the irrigation demonstration was

determining how to reduce the labor costs and obtaining a short term loan to

have the cash for the labor during the next four months. The first of the oil

palms would be sold that summer. It was clear the GDU with his guidance had a

good grasp of the current finances. The irrigation would be something that

could improve the operation’s finances and all members were interested.

Demonstration

Involved People

|

First site visit was on a Sunday afternoon with enthusiastic association members

|

|

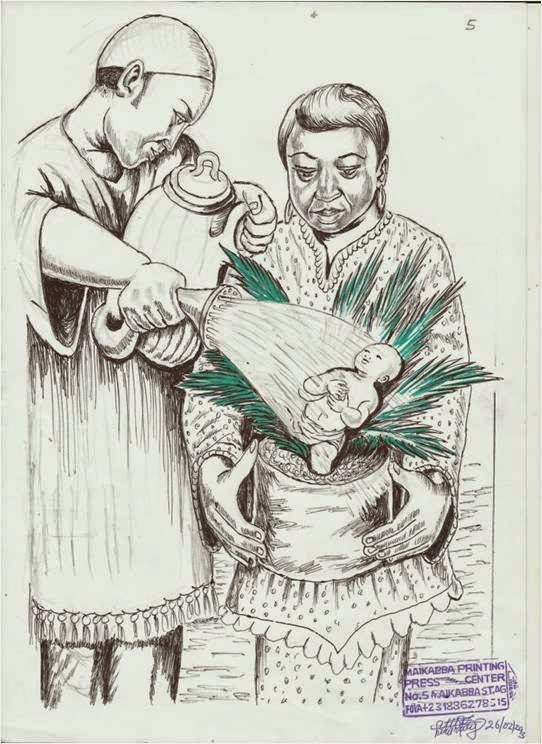

Local artist used for Extension Outreach to

other Nurserymen Irrigation System tasks recorded

|

Several man-hours had been invested in the fall-winter

of 2012-13 preparing for the Demonstration. The GUD had established a nursery

protected with a bamboo fence and water supplied from a good well. Assessment

of the site prior by the WINROCK staff indicated a nearly level plot of land ¾

of a hector near a good road.

Since the primary objective was to demonstrate to the

other nursery operators it was suggested to have a local artist record progress

of the demonstration. Each task in the system would then be communicated

visually with an African perspective. This was important when considering the

number of difference communities, tribes and dialects across the Liberian

interior forest region.

Palm

Oil – Market Developed

|

A five gallon Jug brings $35 to $50

|

|

Hand Power Kernel Oil Press

Replaced destroyed factories

|

Seedling

Nursery – Industry’s Future

|

Operator looking to demonstration for guidance.

Small Operations, little understanding of fertilizer,

horticultural husbandry or

irrigation. |

|

Dry season one half the year. Water carried

100 ft or more to barrel before distribution.

|

Outreach

Combined with Hands On

|

English official language, but several local Dialects' spoken.

Artist’s drawings to bridge communication to

Tribes. |

|

Skills instruction use of tools and methods.

Project tasks in 2 hour blocks due to heat.

|

Project

Concept and Water Critical

|

Agriculturial Economics: Labor, Land/Water, Capital & Mgt. Enterprise’s Business Plan - Reduce labor Objective - Reduce walking to hand water and to increased number of seedlings

|

|

| Combined Irrigation and Nursery Operation Plan with Business Plan Development to maximze resources |

Ensuring that the project fit the African enterprise

business model was an important corner stone to the approach to solve the

design problem. The GUD did have a business plan. Analysis of the plan

indicated that the cost of labor was high and warranted reducing the labor

cost. The oil palm production experts knew that husbandry of the seedling

required daily observation, control of disease and insects also require daily

observation. The industry demand will require a higher number of seedlings.

Considering these factors the GUD object was restated to state “reduction of

the walking required to water the oil palm seedlings” This approach avoided the

high cost and maintenance demanded of individual drip lines and allowed better

husbandry methods by integrating a irrigation system with the African model.

Plan

Development

|

Site survey necessary to design irrigation system

due to distance and lift from well to nursery.

|

Plan development requires accurate inventory of the

resource. Survey techniques were demonstrated to the GUD members. A hand level

and 100 foot tap was brought for this purpose. A survey rod was made at the

local carpenter shop from a mahogany board.

The existing nursery site was located between roads on

high ridges. The nursery water supply was at the bottom of a hill. In some

cases the water was too far vertically in elevation for the hand power pump to

pull/push the water to the nursery. In GUD’s case a faulty pump also hamper the

demonstration.

The value of having a analyzed plan before investing in

the irrigation equipment was demonstrated to the GUD members. When the other

nursery operators in other districts were shown these plans they request having

similar plans developed.

Skills

and Hand Labor

|

Only one individual in ten would have the correct skill. Learning

experience for group.

|

|

Treadle Pump ‘s 2nd trial run Hand labor limited efficiency

|

Installing an irrigation system requires construction

skills. Accurate measurements, square and smooth cut of the pipe that allow

tight fitting joints was demonstrated and practices by the GUD members. There

was one skilled carpenter, blacksmith and assigned secretary educated in

bookkeeping to help the GUD members with the project. This core team and the

GUD labors formed the group that solved each of the installation problems

presented. The energy level of the workers was very good if employed within the

family responsibilities demands and normal meal schedules. Normally two to

three hours work days could be planned. In two cases the work was pushed from

9:00 to 1:30 to complete phases of the installation. The need was communicated

by the GUD leaderships and accepted by the enthusiastic workers. In one case a

100 CM pit was dug in one morning after the ground had been soaked by the

second trial the day prior. The heavy work required a 200 meter bamboo fence

built, a 14 foot deep and five foot diameter well was dug. The first pump

required a level platform to be build which was accomplished in one afternoon

where all GUD members both men and women participated. The GUD member proved to

be intelligent, hard working and willing to adopt new methods.

Artist

Skills and Teaching Husbandry

|

Blacksmith help solve problem of connecting pipes to barrel.

Created a water tight reservoir.

|

|

Outreach’s Motto

Care for each Seedling as you would for your Child

|

Some problems required time to solve. The local material

requirement provided challenges. The African artisans had developed hand craft

skills to make what they needed. This was important. Construction of a small

water reservoir was central to the irrigation plan had to rely on a local

artisan’s handcraft skill. It was fortunate that a competent blacksmith lived

on the next ridge from the project.

Product improvement is possible when proper husbandry

techniques are followed. Fostering husbandry was the motto we encouraged the

workers to consider the seedlings needed the same care the workers would give a

child. In the past the lack of concern for the seedlings was demonstrated by

under watering, lack of fertilizer application, lack of culling disease plants

or treating for insects. Training in how to judge when the soil had adequate

moisture was part of the training. It is hoped that these husbandry techniques

are broadly adopted.

Project Quickly Brought Water to Center of Nursery

|

Second Treadle Pump used this 70 gal. drum as a reservoir

to move water further up slope

|

|

|

Third trial used motor pump. Instruction on

priming the Pump. Required two

days.

|

Rather than spending days inventory and analysis on the

project employment of the foot power treadle pump was quickly made. By

completing the inventory and analysis in the months prior I was able to deliver

water to the lower one third of the nursery early in the demonstration. This

did give the workers encouragement and allowed for enthusiasm to carry past the

problems created by the miscalculation of the elevation that water had to be

raised. The demonstration of the motor pump quickly followed the second treadle

pump. This pump did not operate at the same capacity as the first pump, but

time was not spent on a full analysis of the cause. This process of moving past

problems kept the audience’s attention on each of the four different

demonstrations to bring water into the nursery.

Operation of the motor pump determined that it was

difficult to operate with a large crowd. The crowd size limited communication

for an operation that was more detailed and required closer coordination. On

the second day with the motor pump it was fortuity it was market day. Most of

the audience attended the market. A small crew of three went to different site

by a river to test the pump. Instruction how to prime and operate was easer

taught at this location. Then with the smaller audience the test was completed

successfully later that morning at the nursery. In the Kissi dialect it was a

“Charily Mumba Day”!

Reservoirs

used to store water

|

Success – Water

in Reservoir A rented 1,000 gal. tank

reated goal to reach with business profits.

|

|

Hand watering allow more time to inspect seedlings, reduce

overwatering and potential disease

|

The 1000 gallon water tank was found in Foya was almost

serendipity event. Originally it was determined such a tank was too costly for

the scale of the operation envisioned. This was before a proper survey

inventory of the nursery had been conducted. Use of the rented large water tank

enabled the GUD members to see what a full scale operation required and could

provide the nursery. The well did have limited capacity. It could only provide

700 gallons before the water level was too low. Fortunately the well fully

recharged in just four hours. A 5,000 seedling nursery will require 1,400

gallons daily in the dry season. The GUD determined, based on the

demonstration, that a second well will be needed when they expand.

Hand watering the individual palm was the system

envisioned early I the planning stage. The concern for control of the disease

Blast guided the training not to over water with hoses, but to use buckets that

had liter marks on the bucket. An agronomist provided instruction on the

control of insects, proper mulch material to use and discarding of sick

seedlings.

Challenges

|

Power outage required adapting and overcoming. Planning done

each night prior. Report was due on day returned.

|

|

Porluma Poma farmer uses Machete ,the African multi tool

to install air vent in African reservoir |

Written reports were required by both the Host Nation

and the NGO Sponsor. Making the time to write the report after field work each

proved to be a challenge. Since Foya only had electric power after dark this

became limitation for the report development. I did move to a different guest

house which was linked to the hospital that had power four hours in the morning

and earlier in the evening. I took one morning off to work on the report after

which I was able to complete both reports in the remaining evenings. One

evening a rare thunder storm did knock the power out. I was able to use candles

to see the keyboard and complete one final design problem. Also I used the

candles when working early in the morning. This was important to prepare

designs before going to the project site.

The long term water reservoir was designed using four 70

gallon drums and it had to be designed with a motor pump that was too large for

the system. Air vents had to be cut into the top drum and additional tee-joints

added for air vents in the supply pipes. This allowed for full operation. The

pump could provide over 200 gallons of water in just three minutes. The 2,100

oil palm seedlings were given one liter of water a day. The pump which was the

smallest found by the approved dealer could provide their needs in just ten

minutes.

Future

Plans

Conservation Planning Approach

Conservation Planning Approach

The picture above shows: USDA – Conservation Planning

Nine Step Process. This is the land user’s concept of how to make a irrigation

process work for him. This is the result of the nine step planning process

close daily work with the GUD members using the conservation planning approach.

After corresponding the months prior and the ten days of

the demonstration the farmer’s irrigation plan for the 2014 nursery had

crystallized in his mind. The temporary 200 to 280 gallon four drum reservoir

would serve until a large tank could be afforded. This large tank is important

to provide backup water for the seedling nursery. The plan would be to have the

water tank full for the next day. This would allow time to repair the motor

pump when it required maintenance and to use hand power pumps as backup. In

addition four smaller water storage pits will be located in the center of the

nursery. These 4 by 4 by 4 foot pits would be lined with mud brick and

plastered with cement and have a thick concrete floor. The water tight pits

would provide 480 gallons of water to be hand bucketed and provide close water

close to

the nursery. The cost was estimated if spread over three years to cost just 10

cents per oil palm seedling. The additional costs of the supply and manifold

water lines, the valves and other irrigation material will be covered by the

increase in production. The labor saved by not needing to carry water from the

distant wells would be used to better care for the additional seedlings.

The

Team

|

Volunteer, Lofa Extension Agent and

Team Driver

(GUD Secretary inspects finial reservoir) |

What will have more influence on the future of

Africa? Western farmer to farmer events

like this one coupled with guidance by our foreign ambassadors. Or will it be

the Chinese and other resource exploiters’ influence which all ready can be

seen in public buildings Chinese architectural design in the roof gables? I saw

a number of indicators of a wide variety of influencers. The strongest were

still the Africans themselves. Their ability to retain culture, language and

core values of family and religion has played an important role for generations

dealing with outsiders. This trait to adapt is a core value. One good example

was the adoption of the religious use of choirs that take traditional songs and

adapt a local message. The one dialect choir had a song about the Israelites

leaving Egypt and then the lyrics included the line “we will not return to the

plantation”. Other men said they did not want to end up working for a

plantation. This is a strong forces. But there were a large number of other

strong forces pulling the people of the continent in a tangle of different

directions.

On the plane home I had the opportunity to discuss our experiences with several people. A Belgium architect’s discussion of his work on a new building was one such indicator. He had the same opinion of the Chinese material being sold in Liberia. But he used Chinese's peasants as he called them for construction labors and had building material shipped in from Europe. In no circumstance would he use or consider training Liberian workers. If never given the chance how will the Liberians learn skills or develop value added enterprises to better market their natural resources? Other indicators included observing the large scale endeavors that failed. Across from the German mission in Foya were a dozen 20 foot containers full of several million dollars worth of agricultural equipment. These were left from a failed large scale development. The story the locals told me was the manager did not understand how to use his local labor. That he had them walk for two hours to the job site each day. Little work was ever carried out. Near the customs office on the Guinea border was several tractors just abandon by the Gadhafi regime after Libya fell. Talking with a Netherlands agriculture plant researcher for the International Tropical Institute they plan to pull back from Lofa. Her experience with the bad roads and the difficulty of working in the remote county their organization was giving up. Talking with a German agronomist she was most doubtful concerning many of the small scale endeavors, but that did to dampen her willingness to accept another private donor’s project.

Certainly any effort as I completed one should want to

see it succeed. That does not mean it is carried out as we would in America.

Our democratic system is certainly one to emulate, but not necessarily copy.

Affrication of the enterprises that this region has a economic comparative

advantage makes sense. As long as we can shape the progress for the peaceful

development in the region which does not ever require an adventurous

involvement of American servicemen, the development of a functional economic trade

partner which embraces many of the values we can support that would be the

definition of success. Yes in ten or twelve years it would be nice to see this

area again and see what suggestions were kept and how the many others were

adapted to the African way.